Warehouse Management System Automation in 2020: What to expect?

Business process automation, also known as digital transformation or business automation, is embracing all the industries gradually. According to Digital Trends Report 2019 by Adobe, integrated technology infrastructure is critical for successful customer experience. The report further reveals that businesses are using Artificial intelligence and machine learning capabilities for business process automation.

A warehouse management system is no exception as it directly affects the performance of the supply chain and thus plays a significant role in ascertaining the quality of customer experience. Therefore, when considering warehouse management software in 2020, it is essential to consider the benefits of warehouse automation and the technologies stack that contribute to building an automated warehouse system.

Warehouse automation will critically impact the capabilities of 3PL companies, warehouse operators, transport companies, and distribution centers in 2020. Before discussing the benefits of automated warehouses for different stakeholders, let's begin by understanding the concept of warehouse management system automation.

A warehouse management system is no exception as it directly affects the performance of the supply chain and thus plays a significant role in ascertaining the quality of customer experience. Therefore, when considering warehouse management software in 2020, it is essential to consider the benefits of warehouse automation and the technologies stack that contribute to building an automated warehouse system.

Warehouse automation will critically impact the capabilities of 3PL companies, warehouse operators, transport companies, and distribution centers in 2020. Before discussing the benefits of automated warehouses for different stakeholders, let's begin by understanding the concept of warehouse management system automation.

What is Warehouse Management System Automation

As the name suggests, an automated warehouse system is a congregation of technologies like robotics process automation, artificial intelligence, automated storage and retrieval systems (ASRS) and autonomous mobile robots combined with warehouse management system (WMS) that replace human efforts smartly while increasing the efficiency of the warehouse by leaps and bounds.

Warehouse automation intends to cut down the costs and time invested in manual labor due to which inventory moves slowly. Moreover, manual movement of goods is always prone to errors and malfunctions that affect resource efficiencies. It is possible to control value leakage by reducing the number of touchpoints, as goods move within a warehouse.

For example, Alibaba-affiliate Cainiao has opened a warehouse in China with 700 automated guided vehicles for parcel pick-up and delivery within the warehouse. By leveraging automation in the warehouse, Alibaba targeted to deal with Singles Day demand in 2019.

Warehouse automation intends to cut down the costs and time invested in manual labor due to which inventory moves slowly. Moreover, manual movement of goods is always prone to errors and malfunctions that affect resource efficiencies. It is possible to control value leakage by reducing the number of touchpoints, as goods move within a warehouse.

For example, Alibaba-affiliate Cainiao has opened a warehouse in China with 700 automated guided vehicles for parcel pick-up and delivery within the warehouse. By leveraging automation in the warehouse, Alibaba targeted to deal with Singles Day demand in 2019.

How Warehouse Management System Automation Removes Bottlenecks

The value of an automated warehouse coupled with a reliable warehouse management system, can't be underestimated. A fully automated warehouse addresses multiple challenges faced by modern warehouses in the current context, where they have to process thousands of orders in a day. The major problem is to reduce the cost while at the same time improving productivity. This may sound simple, but can be a daunting task in a warehouse spanned in thousand square feet and have hundreds of employees.

Moreover, it can be dangerous and unsafe for employees to work at a faster speed to meet the expectations. The safety of the employee is equally important, and a hazardous work environment can call for long term consequences.

Warehouse automation can solve such problems while affecting the bottom-line of the business. For example, Goods-to-person technologies (GTP) pick items and bring them to workers in the warehouse mapped on WMS integrated with ERP. AS/RS is also a picking technology that retrieves and stores items back to their place automatically. Pick-to-light systems include an LED display guided mechanism that tells the operator to pick the right item and scan it. Robots replace human efforts and are more accurate and faster. Additionally, warehouse automation allows allocating human resources in management and planning work. Robots and automatic mechanisms can easily handle the extra workload without straining the human capacity, thus ensuring a safe work environment.

Automated warehouse systems are gaining popularity in business space, as more and more companies will look forward to improving the process efficiencies by incorporating advanced technologies in 2020.

Now it is clear that automation is the right solution to all challenges; let's now explore the concrete benefits of an automated warehouse system.

Moreover, it can be dangerous and unsafe for employees to work at a faster speed to meet the expectations. The safety of the employee is equally important, and a hazardous work environment can call for long term consequences.

Warehouse automation can solve such problems while affecting the bottom-line of the business. For example, Goods-to-person technologies (GTP) pick items and bring them to workers in the warehouse mapped on WMS integrated with ERP. AS/RS is also a picking technology that retrieves and stores items back to their place automatically. Pick-to-light systems include an LED display guided mechanism that tells the operator to pick the right item and scan it. Robots replace human efforts and are more accurate and faster. Additionally, warehouse automation allows allocating human resources in management and planning work. Robots and automatic mechanisms can easily handle the extra workload without straining the human capacity, thus ensuring a safe work environment.

Automated warehouse systems are gaining popularity in business space, as more and more companies will look forward to improving the process efficiencies by incorporating advanced technologies in 2020.

Now it is clear that automation is the right solution to all challenges; let's now explore the concrete benefits of an automated warehouse system.

What are the Benefits of Warehouse Management System Automation

1.Increment in speed: Automation is meant for improving the speed of the tasks while ensuring zero errors. An automated warehouse is known to process more orders in a day as compared to its manual counterpart. Automated systems improve order picking efficiency, optimize routes, and help in identifying the exact coordinates of items that significantly reduce the order processing time.

2.Optimal utilization of space: Space constraint becomes a significant limitation as inventory count increases. With more humans around, it is difficult to store items on the aisle as well as on high shelves, as it increases the probability of accidents. However, robots are auto-programmed to operate in the less-spacious environment, thus facilitating an optimal utilization of warehouse space.

3.Reduction in costs: Rising costs curves always pose challenges for the businesses. Automation permanently resolves these issues. However, on the upfront, implementation of warehouse system automation is an expensive strategy, but it starts paying off well at an early stage. The ROIs are positive and encouraging for businesses to opt for warehouse automation. Furthermore, automation easily supports warehouse activities during peak seasons, special events, and holiday season by 24*7.

4.Improved inventory management: Undoubtedly, as human errors are minimized with a tangible gain in overall productivity, inventory management gets streamlined. An automated warehouse management system maintains accurate inventory data with exact counts, thus helping managers to plan preemptively.

5.Safe work environment: Needless to say, automation allows proper utilization of floor and shelf space, thus creating minimum traffic on the floor and eliminating the chances of human accidents.

5.Safe work environment: Needless to say, automation allows proper utilization of floor and shelf space, thus creating minimum traffic on the floor and eliminating the chances of human accidents.

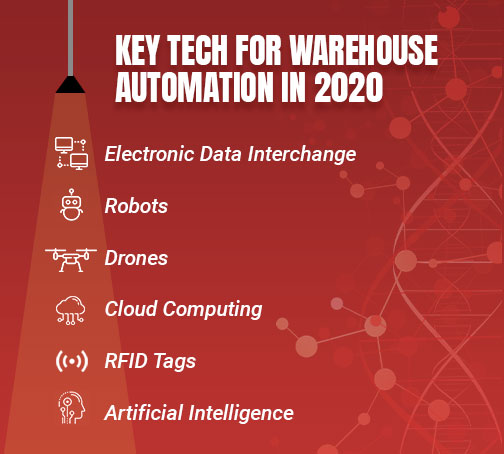

Technology Stack for Warehouse Management System Automation

Technology is a driving force for modern data-driven organizations that need to make decisions based on real-time information. So, if your business has been relying on conventional ways of warehouse management system, it is high time to switch and adopt technological innovation for long term sustainability. According to a study, 'Warehouse Automation Market,' published by LogisticsIQ™, the warehouse automation market is estimated to reach $27 billion by 2025.

The figures indicate the immense scope for implementing automation in the warehouse management system. Companies can save thousands of dollars as manual errors, and turnaround time gets reduced. Let's focus on some of the critical technologies that will mark the presence of an automated warehouse system in 2020

The figures indicate the immense scope for implementing automation in the warehouse management system. Companies can save thousands of dollars as manual errors, and turnaround time gets reduced. Let's focus on some of the critical technologies that will mark the presence of an automated warehouse system in 2020

1.Electronic Data Interchange: EDI is a data communication technology between various computer nodes connected in a network. EDI gets integrated with WMS and supports the sharing of data and other documents between different trading partners, including vendors, shippers, suppliers, and other channel entities.

2.Robots: Robots play an instrumental role in automated warehouse systems. They augment human efforts and ensure that they remain engaged in strategic tasks while all manual functions, including picking, sorting, loading, packing, retrieving, and storing, are handled by robots. The use of automation in warehouses, especially robots, has a positive impact on deliveries and thus customer experience. Alibaba's Warehouse is an excellent example where 60 robots where each robot can lift 500 kilograms of weight without colliding with each other and are connected through wifi.

3.Drones: Drones are widely used by distribution centers these days. Modern automated warehouses are relying on autonomous drones for picking, packing, sorting, scanning, and selecting tasks. Companies are using drones for counting inventory. The warehouse management system (WMS) gets integrated with drone's software due to which drones can track the exact location of the item and complete the desired action.

4.Cloud Computing: Cloud-based systems much support warehouse automation. By installing WMS that are available as SaaS (Software as a Service), organizations do not need to maintain IT infrastructure, as complete data is available on the cloud. Businesses are nowadays migrating their legacy systems to cloud to leverage the potential of cloud computing.

5.RFID Tags: Radio Frequency Identification has been widely used in warehouses to transfer data between digital labels. A digital tag is a smart replacement of paper tags that are torn off and may hamper stock visibility. But with special scanners, the items with RFID tags are scanned and regularly updated, and data is stored on the warehouse management system.

6.Artificial Intelligence: Pick Path Optimization, and other AI capabilities are striking features of the automated warehouse system. An intelligent pick path algorithm calculates optimal routes to traverse in a warehouse; thus, order pickers can save enormous walking time and increase warehouse efficiencies.

Finally,

2020 will witness a proliferation of automation in warehouses where small and medium scale companies will go for warehouse management system automation to improve the overall productivity of their supply chain. AI, Robotics, and other smart technologies will catalyze the warehouse processes while making them faster, accurate, and intelligent.

CeleroWMS by Katalyst Technologies is an advanced Warehouse Management Solution focusing on the specific requirements of apparel, footwear, accessories and other industries for warehouse automation. It offers effective and efficient warehouse operations such as picking, packing, shipping, and cycle counting along with AI capabilities in wave picking and the allocation process.

CeleroWMS by Katalyst Technologies is an advanced Warehouse Management Solution focusing on the specific requirements of apparel, footwear, accessories and other industries for warehouse automation. It offers effective and efficient warehouse operations such as picking, packing, shipping, and cycle counting along with AI capabilities in wave picking and the allocation process.